EHT Installation

► Procedure of EHT Installation

● Design Drawings

● Thermostat Installation

● Preparatory Work

● Insulation Installation

● Installation of EHT

● Testing

● Accessories Installation

● Testing & Record

Electric trace heating is an effective pipeline insulation and anti-freeze solution, which has been widely used. Its working principle is to distribute certain heat through heat tracing media, and supplement the loss of the pipeline being heated by direct or indirect heat exchange, so as to achieve the normal working requirements of warming, heat preservation or anti-freezing.

After the water freezes, on the one hand, it cannot flow; on the other hand, the density of ice is smaller than water, and the volume of the water of the same quality becomes bigger after freezing, thus bursting the pipe. Therefore, it is necessary to take anti-freezing measures, and one of the methods is electric tracing heat.

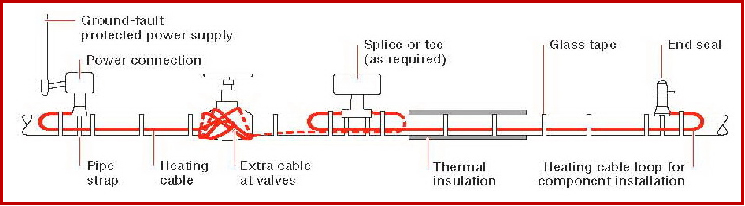

There are many kinds of methods for the installation of electric tracing heat, the first is to use a single electric tracing heat construction method, this way is the glass fiber pressure-sensitive adhesive tape electric tracing heat fixed on the pipeline, everything according to the design can be, generally speaking, above or below, another way is the spiral winding, is the aluminum tape spiral winding way winding in the pipeline, and fixed. The third way is to use more than one electric accompaniment heat construction method, is more than a few glass fiber pressure-sensitive adhesive tape these winding way.

1. In the construction of laying, electric accompaniment tapes are strictly forbidden to fold and hammering knocking, but also can not impose too much tension, to avoid insulation damage, electric accompaniment tapes line short circuit phenomenon. Need to accompany the heat of the pipeline, flange and other equipment instrument surface should be smooth and flat, no sharp edges, so as not to scratch or damage the electric accompanying tapes in construction or later use.

2. Electric heating cable laying using parallel straight winding. Wave winding, spiral winding and other ways to carry out. In the use of wave noisy and spiral winding way laying, do not exceed the minimum bending radius. Excessive folding bending, may or due to the internal structure of the change, resulting in local breakdown of the fire phenomenon.

3. Strictly install the design requirements for construction. In accordance with the design of the required accompanying heat load, to ensure that the pipeline reasonable electric accompanying tropical length, too much laying or too little laying are not conducive to the reasonable use of electric accompanying heat and power saving and consumption reduction.

4. In order to ensure the uniform heat dissipation of the electric heat tracing system, electric heat tracing should be close to the surface of the pipeline, and aluminum foil or aluminum tape for adhesive fixed, both increase the heat dissipation area, is conducive to heat conduction, and easy to install the construction of heat tracing.

5. When installing insulation layer, glass wool and other insulation materials must ensure dry. Moist insulation materials will seriously affect the insulation effect, but also may be with the tropical corrosion, reduce the service life of the tropical. Insulation material after laying, must be waterproof treatment, if not winding waterproof layer, will greatly affect the insulation effect, increase the power loss.

6. The installation length of the heating tape should not exceed its maximum allowable length, the maximum allowable length depends on the performance index of different models of products.

7. Electric tracing heat system installation is completed, must carry on the electrical insulation test. When testing, need to conduct insulation test for each wiring circuit one by one.